Leading Slip-On Flanges Supplier in Muscat, Oman – Omaa Metal Sources

Why Choose Omaa Metal Sources for Slip-On Flanges in Muscat, Oman?

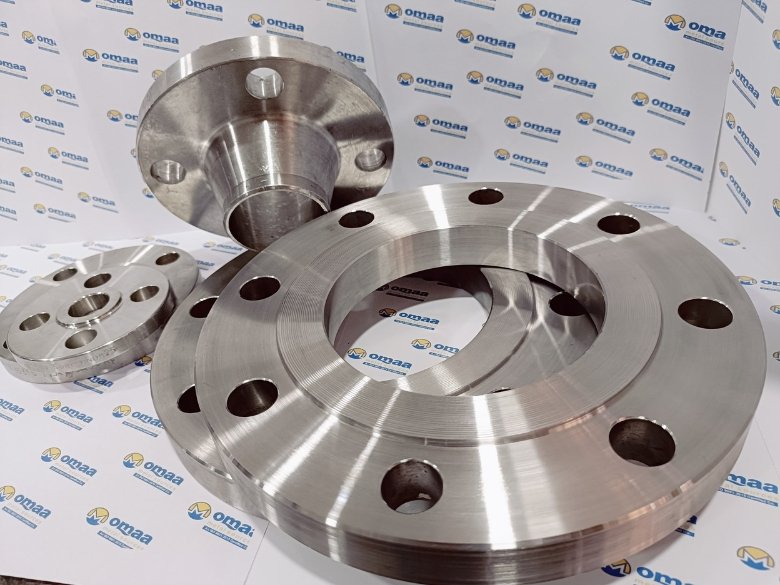

Omaa Metal Sources is a renowned supplier of slip-on flanges in Muscat, Oman, catering to the diverse needs of various industries. Our product range is designed to meet the stringent requirements of our clients, ensuring that they receive top-notch quality slip-on flanges that last.

Benefits of Choosing Omaa Metal Sources

- High-Quality Products: Our slip-on flanges are crafted from premium materials, guaranteeing exceptional strength and durability.

- Reliable Services: At Omaa Metal Sources, we pride ourselves on offering timely and cost-effective solutions, ensuring that our clients’ needs are met with utmost satisfaction.

- Competitive Pricing: We offer competitive pricing for our slip-on flanges, making us one of the most affordable suppliers in Muscat, Oman.

Applications of Slip-On Flanges

Slip-on flanges are versatile and can be used in a variety of applications across various industries. Some of the most common applications include:

- Piping Systems

- Valves and Fitting

- Boilers and Heat Exchangers

- Pumps and Compression

Why slip-on flanges in Muscat, Oman?

Muscat, Oman is an emerging hub for the oil and gas industry, driving the demand for high-quality slip-on flanges. Omaa Metal Sources is well-positioned to cater to the needs of this ever-growing industry by providing reliable and cost-effective slip-on flanges.

Our team is dedicated to ensuring that our clients receive the highest level of service, ensuring that their needs are met with utmost satisfaction. If you’re looking for a trusted supplier of slip-on flanges in Muscat, Oman, look no further than Omaa Metal Sources. Contact us today to learn more about our products and services.

Reference: Slip-On Flanges Supplier reference